Oil & Gas

SUDEL has nearly 30+ years of experience servicing clients in the oil and gas industry.

We run a dynamic operation that provides flexibility to ensure clients objectives are met within the time frames specified, with the ability to deliver faster response times than the OEMs, to the service and quality expected.

Our field teams are qualified and accredited to work in remote and hazardous areas of the major basins in Australia, from the Cooper Basin, Eromanga Basin and Amadeus Basin through Central Australia to the Eastern Bowen Basin and Surat Basin, and Southern Otway Basin. Our technicians are also experienced in project delivery and maintenance activity supporting offshore facilities.

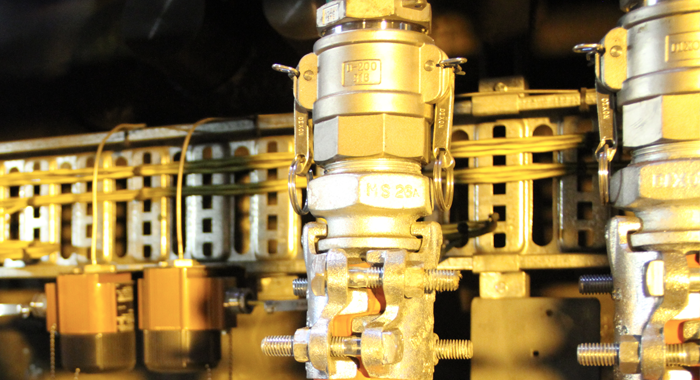

Our diverse experience across upstream, midstream and downstream facilities makes Sudel suited for one off urgent jobs, routine instrumentation calibration and/or scheduled site shutdown work.

Clients have confidence that we can have a team onsite quickly to keep operations moving, and to service instrumentation and associated equipment through our strategically placed network of service centres.

With personnel experience in all areas of electrical and process instrumentation, Sudel is an obvious choice.

Our clients include asset owners, asset operators, service companies and OEMs. Over the last 20 years, we have delivered project services to clients including Origin Energy, SANTOS Port Bonython, BHP OD LPG systems, APA Group, Halliburton, Beach Energy, Weir Oil and Gas and Ice Engineering.

In addition to our work in Oil & Gas, we have a strong relationship in servicing client work in the field for large scale industrial processors BHP, GFG and Simec Mining (formerly Arrium) built over the last 30+ years.

Our Quality Systems are certified to ISO9001 Standards.

We perform all testing and calibration to meet Australian Standards requirements, and in accordance with NATA standards - utilising the latest high spec test equipment that is certified by NATA accredited laboratory and supported by our ProCal V5 online support system that provides real-time asset management reporting capability.

We also provide qualified technicians to undertake regular PRV (Pressure Relief Valve) inspection and testing (generally every 1-2 years in-service testing dependant on the type of pressure vessel; following repairs or at commissioning/recommissioning).

OUR TRACK RECORD

Port Augusta Power Station, Flinders Operations, Value

View

Smelter Shutdown, BHP Billiton, $250,000

View

Blast Furnace Repair, Leighton Contractors, $2M

View

Sx fire wire, BHP Billiton, $500,000

View

SULPHUR MELTING TANK, BHP Billiton, $1M

View

Plant Low Voltage Connection, BHP Billiton, $500,000

View

SUDEL’s Safety Approach

View

OUR CERTIFICATIONS

OUR ASSOCIATIONS